Fluid Handling Pumps Product List

Compact Diaphragm Paint Pump DPS-70C Series

Applications

- Automotive Refinishing

- Automotive Industry

- Metal coating

- Plastic coating

- Woodwork coating

- Ironwork coating

- Building coating

* The agitator shown in each image is optional.

* The pump does not come with a pail.

Features

- Space-saving single-gun type most suitable for those who consume about 20 liters of paint per day.

- Recommended for those who change colors very often with a paint tank or who use a suspended gravity type tank.

Medium-sized Diaphragm Paint Pump DPS-90E Series

Applications

- Automotive Industry

- Metal coating

- Plastic coating

- Woodwork coating

- Ironwork coating

* The agitator shown in each image is optional.

* The pump does not come with a pail.

* The pump does not come with an elevating stand-type paint can.

Features

- Most suitable for those who use more than 40 liters of paint per day.

- Useful for pressure-feed paint supply to a reciprocator, automatic coating equipment, or coating robot as well as for pressure-feed manual spraying.

Medium-sized Diaphragm Paint Pump DPS-120B Series

Applications

- Automotive Industry

- Metal coating

- Plastic coating

- Woodwork coating

* The agitator shown in each image is optional.

* The pump does not come with a pail.

Features

- Supports a maximum paint output of 30 L/min and capable of handling multiple guns.

- The larger paint passage makes it easy to clean the inside the pump and allows the use of high viscosity paint.

- Useful for pressure-feed paint supply to a reciprocator, automatic coating equipment, or coating robot as well as for pressure-feed manual spraying.

- Multiple guns can be handled.

Compact/Medium-sized Diaphragm Pump (Standalone Unit)

Features

- Stable supply of paint

- Shorter color change and cleaning times

- Rich variety

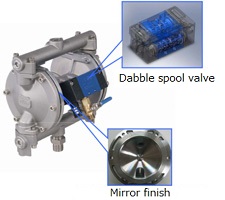

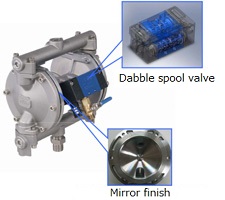

To prevent a pump operation failure (switching failure), we have improved the air-operated valve with the double spool structure originally designed by ANEST IWATA which has been employed in the previous models and adopted this improved valve for all the models. This reduces the risk of stoppage nearly to zero, enabling the pump to be used on lines and with automatic equipment and making it an even more reliable diaphragm pump.

All the models have the inner surface of their paint chamber treated with mirror finish, making it possible to change colors and clean the pump in an even shorter time. This also helps reduce cleaning liquid consumption and the amount of waste liquid.

Depending on the required paint output and paint type, you can choose from a total of eight kinds of pumps. What’s more, we will be happy to present an application that’s best suited to your working environment.

Large-sized Diaphragm Pump (Standalone Unit)

Features

- Stable supply of paint

- Shorter color change and cleaning times

- Rich variety

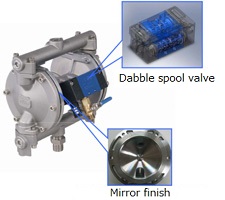

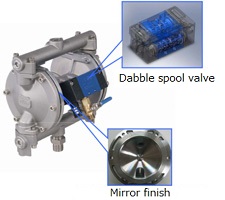

To prevent a pump operation failure (switching failure), we have improved the air-operated valve with the double spool structure originally designed by ANEST IWATA which has been employed in the previous models and adopted this improved valve for all the models. This reduces the risk of stoppage nearly to zero, enabling the pump to be used on lines and with automatic equipment and making it an even more reliable diaphragm pump.

All the models have the inner surface of their paint chamber treated with mirror finish, making it possible to change colors and clean the pump in an even shorter time. This also helps reduce cleaning liquid consumption and the amount of waste liquid.

Depending on the required paint output and paint type, you can choose from a total of eight kinds of pumps. What’s more, we will be happy to present an application that’s best suited to your working environment.

Bellows Seal Pump BSP Series

Features

Prolonged maintenance cycle

The bellows seal separates the paint chamber and the air chamber, which results in a longer maintenance cycle for the sliding parts.

Use with environment-friendly types of paint

The high pressure ratio enables stable supply even for environment-friendly high-viscosity types of paint such as high solid paint and water-based paint.

Use with multiple spray guns

The large paint output per cycle ensures a stable supply of paint even when multiple spray guns are used.

Resistance to water-based paint

The parts that come into contact with liquid have highly reliable fluorine resin coating for water-based paint resistance.

Paint Pump

Features

Paint regulator as a standard component

Since the pump has a paint regulator as a standard component, attaching a spray gun is all that needs to be done to start a coating job.

Also usable as a paint supply pump for a cellular coating facility

When combined with a back pressure valve, the pump can also be used as one for a compact paint circulation system.